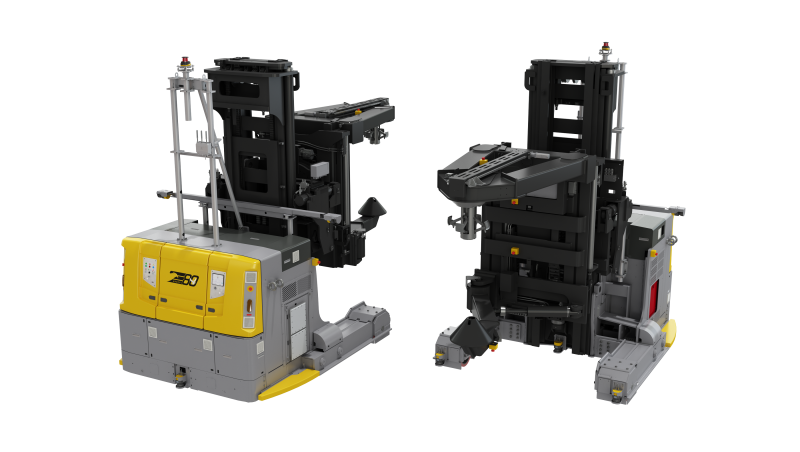

The Unicorn is one of our most innovative patented solutions and is designed to improve the management and automated movement of parent reels.

This solution system incorporates two chucks that engage the inside of the reel core and can lift and deposit reels either vertically or horizontally. The first chuck is expandable and lifts the reel from inside. The second engages the underside of the reel and provides the support needed to rotate it.

Advantages:

High storage heights

- Unicorn can vertically stack reels up to three levels high (reaching 9 meters), and can lift reels weighing up to five tons, thus covering almost the entire range, up to a diameter of 3 meters.

Patented automatic handling system

- The new Unicorn picks up the reel using expandable shafts, no longer relying on clamps

- It guarantees the highest standards of parent reel quality already achieved by the Elephant. In fact, Unicorn avoids squeezing the reels thanks to the replacement of the clamp (which acts by pressure) with the patented handling system.

Reliability and efficiency

- This solution makes it possible not to ruin the paper because it is not touched during the lifting and handling process.

- Thanks to the absence of contact on the external surface of the reel, this translates into zero deterioration and zero breakage of their product, and an almost total reduction in waste.

- Increased utilization of available warehouse space by approximately 6-7% due to the fact that reels can be stored in contact with one another back-to-back.

Flexibility and safety

- Since there is no longer any contact with the outer surface of the reel, reels can be delivered automatically without further intervention, at the right time and in the right place, where they are needed, and keeping their condition intact.

- Unicorn can also automatically handle the reel's spent core, a task that today is handled almost exclusively manually.

- Thanks to the storage of the reels in direct contact with one another back-to-back, the risk of flame propagation in case of fire is considerably reduced, a fundamental index in view of guaranteeing increasingly higher safety levels.

More than 450 integrated solutions

More than 2800 robotic systems

More than 9000 AGVs and LGVs

Since 2016, 50 automated high-density warehouses

Italian

Italian