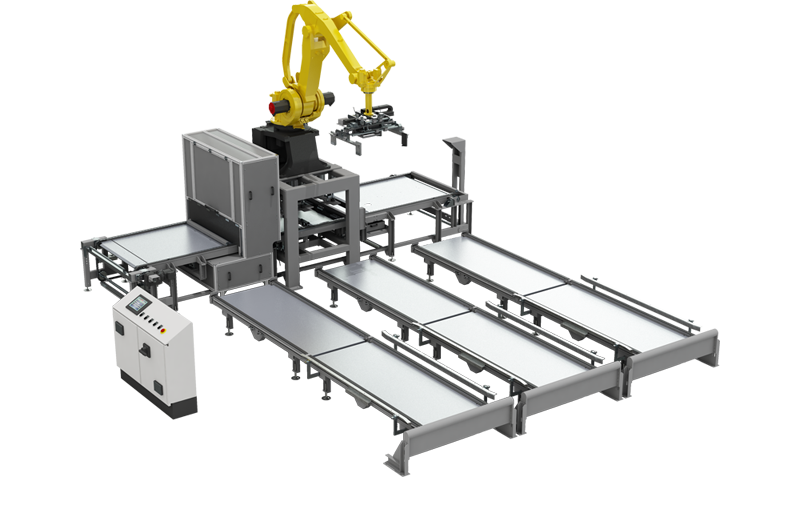

Woodpecker automatic empty pallet inspection system ensures that only pallets complying with the customer’s requirements are used in the manufacturing process.

Woodpecker carries out a complete check of the pallet conditions, utilizing both a mechanical system to measure load resistance and a vision system, to inspect for shape defects difficult to detect for the human eye. This reliable system can manage several types of pallet sizes and colors, with the possibility of setting up a customized “control recipe” through a user-friendly operator interface. The non-compliant pallets are removed from the end of line, eliminating risk to the operator and preventing product from falling during the handling operations inside and outside the factory.

Advantages:

Efficiency and quality

- Use of the vision technology as a quality control dimension for each pallet type

- It improves the efficiency and safety of the processes

Safety

- It ensures only quality-approved pallets in the production process/ area

- It prevents damage to the final product and problems during the handling with LGVs and inside the automatic warehouses

More than 450 integrated solutions

More than 2800 robotic systems

More than 9000 AGVs and LGVs

Since 2016, 50 automated high-density warehouses

Italian

Italian