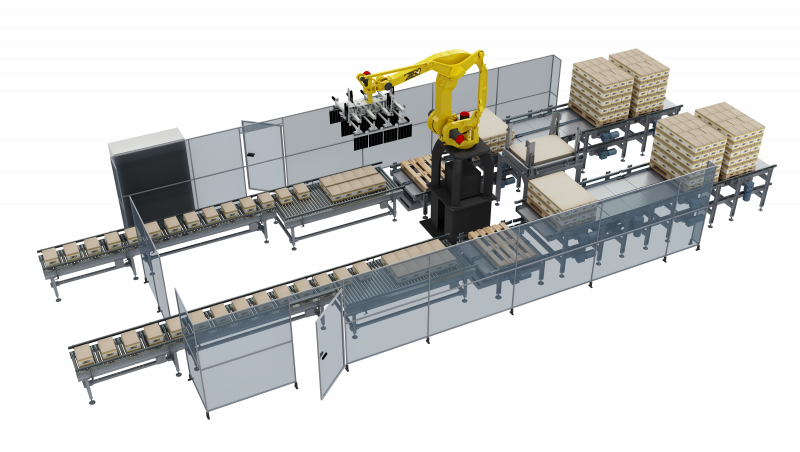

Palletizing system with row gripper

Condor palletizing cell permits the handling of 1 to 4 pallet positions. Gentle handling of packages eliminates the risk of product damage and provides flexibility for stacking various formats on multiple pallet platforms (i.e. full pallets, half pallets, display pallets).

The Condor is designed to be close coupled to the end of the packaging line and is completely accessible from floor level, eliminating the need for expensive platforms and the safety risks associated with working on raised surfaces.

Equipped with operator-friendly HMI and Auto-Pallet Pattern software, the Condor is designed for quick recovery after upset conditions and is even capable of changing to formats never previously processed without having to use the robot’s keyboard.

Finally, Condor palletizing system interfaces with LGV/AGV, perfectly integrating all intralogistics operations within a plant.

Advantages:

Flexibility

- Management of numerous formats, palletizing patterns as well as simultaneous palletizing of products from different lines

Reliability

- Maximum safety during product handling

- Maximum safety when handling empty pallets

Quality

- No product deformation and safe handling without applying excessive pressure

- Precise and constant depositing over time

More than 450 integrated solutions

More than 2800 robotic systems

More than 9000 AGVs and LGVs

Since 2016, 50 automated high-density warehouses

Italian

Italian